| |

Vacuum Generators: AVR, AV, RAV Series (USA threads)

Quickly and effectively generate vacuum in the following applications:

• Removing air or gases from process vessels, tanks or other closed systems.

• Vacuum handling and positioning of small parts.

• Leak testing of various systems.

• Used with vacuum cups in pick-and-place equipment.

• Labeling, packaging and paper feeding machines

• AVR Models available with male or female threads

• Optional Mufflers shown below are available for most models

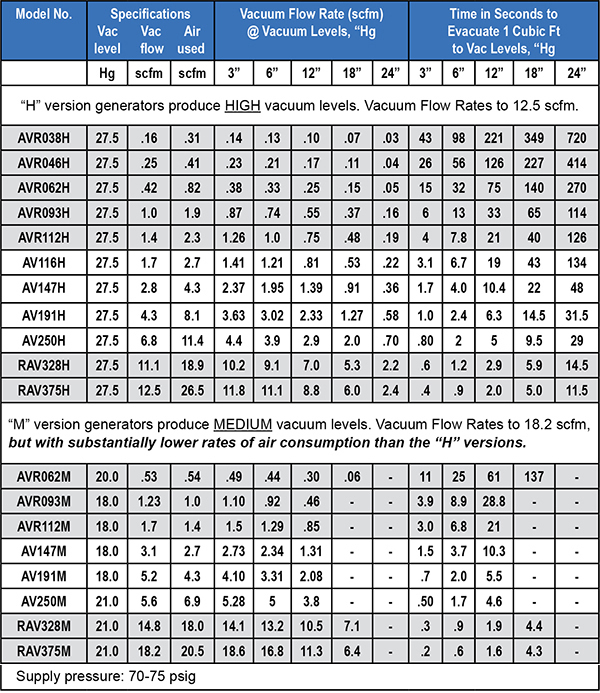

Wide Range of Performance:

• AVR Series: Vacuum Flow .16 to 1.7 scfm, Vacuum Levels 18 to 27.5"Hg.

• AV Series: Vacuum Flow 1.7 to 6.8 scfm, Vacuum Levels 18 to 27.5"Hg.

• RAV Series: Vacuum Flow 11.1 to 18.2 scfm, Vacuum Levels 21 to 27.5"Hg.

When choosing from the chart below please consider:

"M" Series produce MEDIUM vacuum levels for low air usage

"L" Series produce LOW vacuum levels for lower air usage

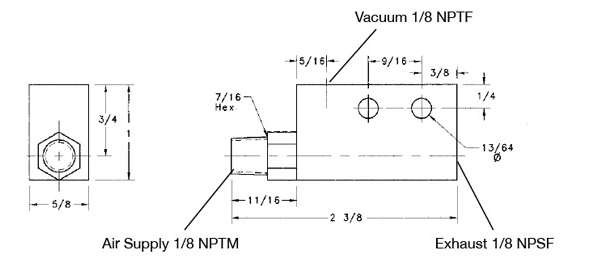

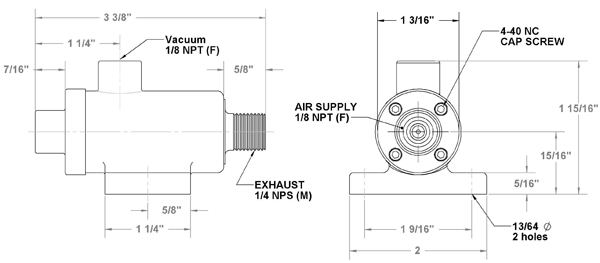

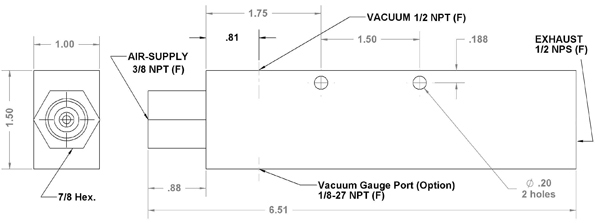

Full Dimensions

AVR Series

AV Series

RAVSeries

|

|

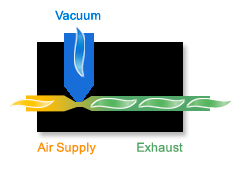

How AV Series Works

Compressed air

flows through a small circular opening to generate a high velocity.

This air expands, resulting in decreased pressure to provide vacuum levels up to 27.5"Hg. The vacuum port is perpendicular to the air supply.

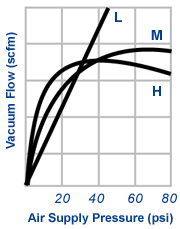

Performance

Considerations

for Minimal Air Usage

Vacuum Levels

Depends on the application,

High, Medium, or Low:

• Select an H Model when

maximum vacuum level is

required, 25-28"Hg

When lower vacuum levels

satisfy the requirement:

• Select an M Model for 15-20"Hg

• Select an L Model for 8-12"Hg

This results in a substantial

reduction in air usage.

Vacuum Flow

Substantial vacuum flow is developed at low operating pressures when using

Models H, M or L.

• Initially the curves are very steep.

The operating pressure at 40-50 psi

provides maximum vacuum flow.

• Higher pressures do not increase the vacuum flow but will increase

air usage.

Applications

Selecting the minimum vacuum level and lowest operating pressure in the following applications

will minimize air usage:

• Leak Testing

• Labeling Machines

• Paper Feeding Systems

• Printing Presses

• Vacuum Chucks

• Sheet Metal Lifters

• Packaging Machinery

• Encapsulating

• Food Processing Machinery

• Air Sampling

• Dental Equipment

• Gas and Liquid Mixing

• Air Cooling

Detailed Specifications

> Download Specs PDF file

3D CAD Models

> AVR Step

> AVR IGS

> AVR PDF

> AV Step

> AV IGS

> AV PDF

> RAV328 Step

> RAV328 IGS

> RAV328 PDF

> RAV375 Step

> RAV375 IGS

> RAV375 PDF

|

|