|

|

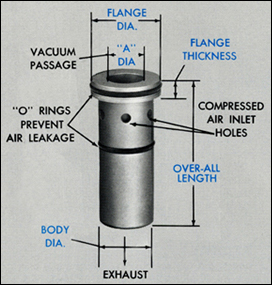

How to Select the Proper Size Vacuum Sleeve |

|

|

To Properly Install Vacuum Sleeves, Follow These

|

|

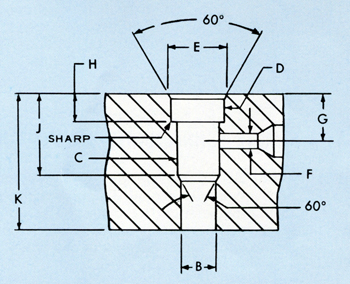

Machining Specifications

|

|

|

|

|

APPLICATION EXAMPLES

|

|

Lamination Die with Multiple Scrap Openings Requires the Installation of Two Funnel Units. For Application #2, the total area equals .645 in2. the size unit required was a VT940 having an "A" diameter of .937" with an area of .690. |

Strip Stock Layout and Die Portion Which Requires Vacuum to Prevent Four Notches and Two Oblong Slugs from Pulling Up with the Punches. Since the total area of the four triangular die openings and two oblong die openings equals .224 in2. A VT560 F2 Funnel Unit was selected which provides a total area of .248 in2. |

|

APPLICATION EXAMPLES

|

| Upward Shave Operation Made Possible by Use of Vacuum The Problem: Due to the design of the part, a trimming operation has to be done upward, otherwise, secondary operation would be required. It is important to keep this shaving (.190 x .020) from falling back onto the surface of the die. The Solution: A TDS260 Vacuum Transducer was selected as the "A" diameter (.260) provides sufficient clearance. The installation is simple, as the tubing is used to connect the die opening to the Vacuum Transducer. By having vacuum in the die opening, the loose shavings pass upward through tubing, Vacuum Transducer, and exhaust hose into scrap container. |

|

|

|

The Problem: To remove the finished part at the final cut-off station. The normal procedure is to used compressed air to blow this part into a container. However, they coould fly in various directions and often do not leave the die area and interfere with the strip stock.

|

Vacuum Increases Uses of Horizontal Press Set-Up This design requires the removal of the center slug that needed to be pierced in a horizontal diretion to prevent the slug from falling onto the die.

|

|